Four, installation notes

1. Place the machine in a smooth place, level it with a horizontal ruler, and adjust the level by adjusting the four iron.

2. Connect the sealed cooling water, the water pipes with the arrows inside to the tap water, and the water pipes with the arrows inside to the drains. The tap water pressure must be greater than 0.1Mpa and the mainframe works.

3, then the compressed air, air filters should be added transformer oil.

4. Connect the power line to the grinder box, three open interfaces on the left, and the fourth open ground wire on the left.

5, the main panel and the pump knob on the control panel should be put to the stop position before sending electricity.

6. Electric main engine, open the lower side board to see if the motor is rotating correctly, if not, arbitrarily change two fire lines.

7, check whether the pipeline is loose or not, and whether the upper pressure gauge and thermometer are connected.

8. Connect the air compressor to test pump and push water into the grinder until the outlet overflows or fills the water into the barrel from the upper part.

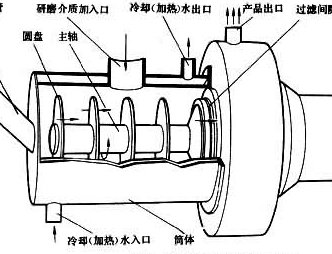

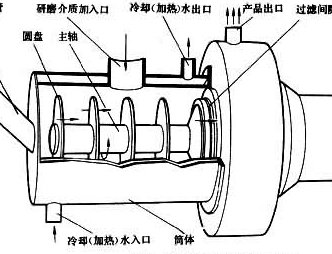

9. Put the glass beads in the middle sand hole on the sand mill for about 15 kilograms and cover tightly. The equipment has been added to the beads before leaving the factory.

Five. Operation rules

Operation sequence:

1. Close the inlet ball valve of the sand mill.

2. Turn on the water cycle and start the main engine when there is water coming out of the outlet.

3. When the main engine is running normally, turn on the working pump and slowly open the ball valve.

The main engine and the pump knob on the control panel are stopped until the electricity is sent. No material idling is strictly prohibited on main engine.

Six, maintenance and maintenance:

1. The main engine is cleaned with clean water after production, and there is a certain amount of clean water to prevent the residual powder precipitation and agglomeration in the gap, which makes the next start difficult and mechanical seal premature damage.

2. After the diaphragm pump works for a period of time, the appropriate transformer oil can be added to the second cup of the air filter to prevent the mechanical operation from abnormal.

3. After 1-2 months of operation (depending on the specific workload), the glass beads should be released for inspection. If there are more beads or broken beads, all the beads should be released for screening. The glass beads less than 1.5mm in diameter should be scrapped and appropriate amount of glass beads should be added.

Keywords emulsion machine, basket type lapping machine, static mixer dispersing machine

|