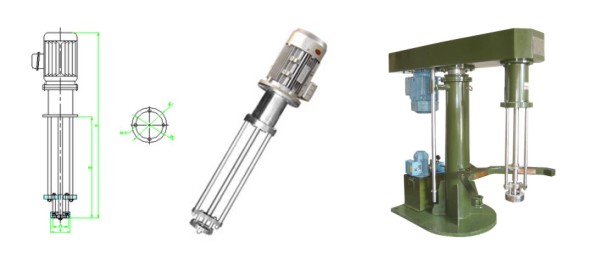

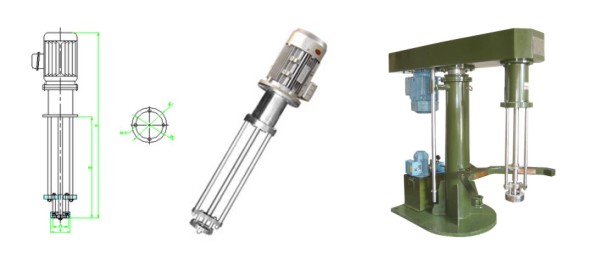

Batch emulsification machine can distribute one or multiple phase to another Continuous phase (usually each phase is insoluble). Industrial batch-type high- shear mixing and emulsifying machine is the top Seller in the SG brand series .It is used widely in many areas. As the core component of this machine, the high shear mixing head can work independently, and it can also be fixed in the mobile frame, reactor kettle or other vessel, to meet different processing needs.

(1) different shapes of stator structure (long hole, meshy hole, and round hole) ,which can meet the performance requirements of different medium, to ensure the better effect of mixing and emulsing.

(2) the gap between stators can be adjusted freely to meet the technical requirements of different products.

(3) particles of the treated material has a narrow range of particle distribution, and good evenness.

(4) two kinds of batch-type emulsifying machine, mobile and fixed , can be used independently or combinated to meet the production processing requirements.

(5)Optional contact surface made from 304 or 316 stainless steel to meet the requirements of the Sanitary.

(6) the full range of specifications to meet different production capacity

(7) flexible operation, small investment, high efficiency, and a wide range of products.

(8) easy to installation and clean.

(9) stable operation, low noise

different kinds o batch-type emulsifying machines are available for selection. Unidirectional suction, bidirectional suction types. unsealed or mechanical sealed types; and portable pneumatic lifting (manual hydraulic )or electro-hydraulic lifting types.

Model Power revolutions processing capabilities kg (water) Dimensions (total length x length) liquid

GRY-101 1.1 2880 100 760*500

GRY-105 4 2880 200 1090*750

GRY-110 7.5 2880 1000 1270*850

GRY-115 11 2880 1000 1480*1000

GRY-120 15 2880 1500 1640*1000

GRY-125 18.5 1440 2000 1960*1300

GRY-130 22 1440 3000 2100*1500

GRY-150 37 1440 5000 2950*1800

GRY-175 55 1440 6000 3500*2100

GRY-1110 75 1440 7000 3900*2400

|